SIRIUS

Portable Braille Embosser

ROLE: DESIGN LEAD, DEVELOPER

08/21 - 12/21

Academic project completed at Cornell University with Kehui Guo, Ingrid Zhu

Instructor: Professor Cristobal Cheyre Forestier

ABOUT THE PRODUCT

Use interactive and assistive technology to shorten the communication gap between users with normal vision and visually impaired people.

This portable braille embosser will translate English into braille and print out tags for blind or visually impaired people.

01 INTRODUCTION

Current Technologies

Braille is a code system in many languages that visually impaired people can write and read with their fingers. Each Braille character is organized in 3x2 rectangular blocks with raised dots aligned in the cells.

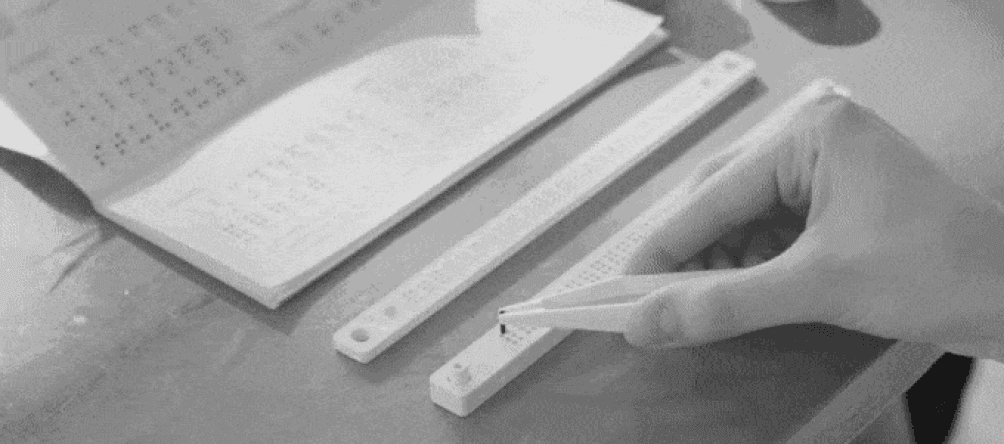

Vrailler

Vrailler is a DIY Braille label kit that has more portability and learnability. However, the mechanism of this product is quite troublesome. The user manually inserting pins into the slate without any automatic proofreading and spell check system increases the likelihood of producing inaccurate content, and the efficiency of writing and printing becomes uncertain.

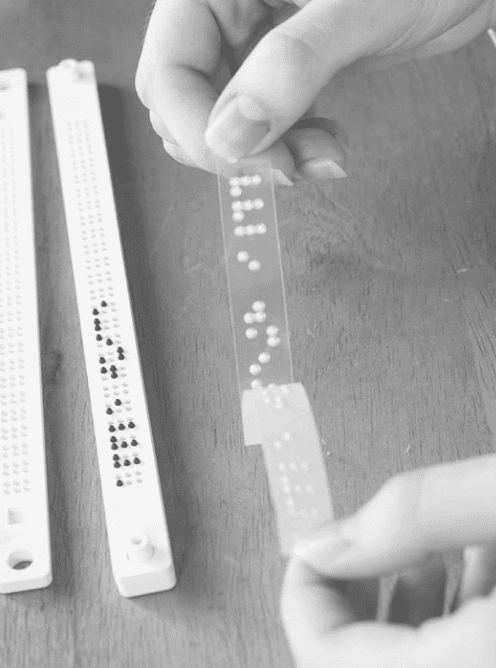

Slate & Stylus

The stylus will be used to create individual braille dots on the slate that has many uniform cells.

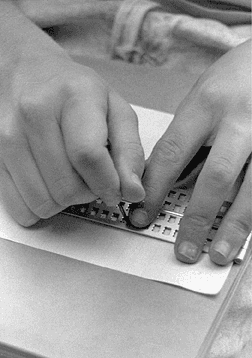

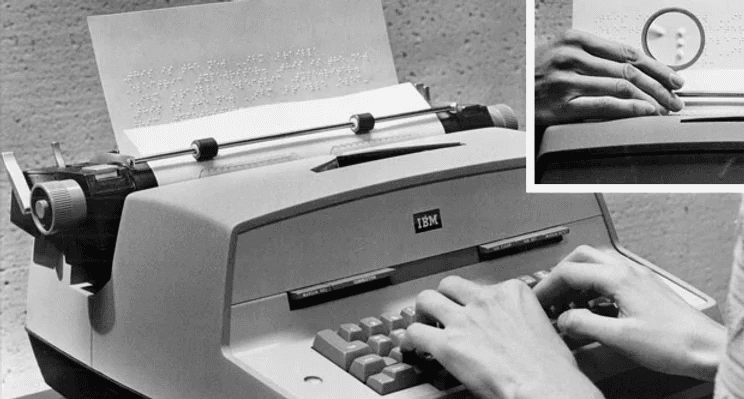

Braillewriter

People can type Braille more efficiently and accurately on the surface.

Innovative Materials

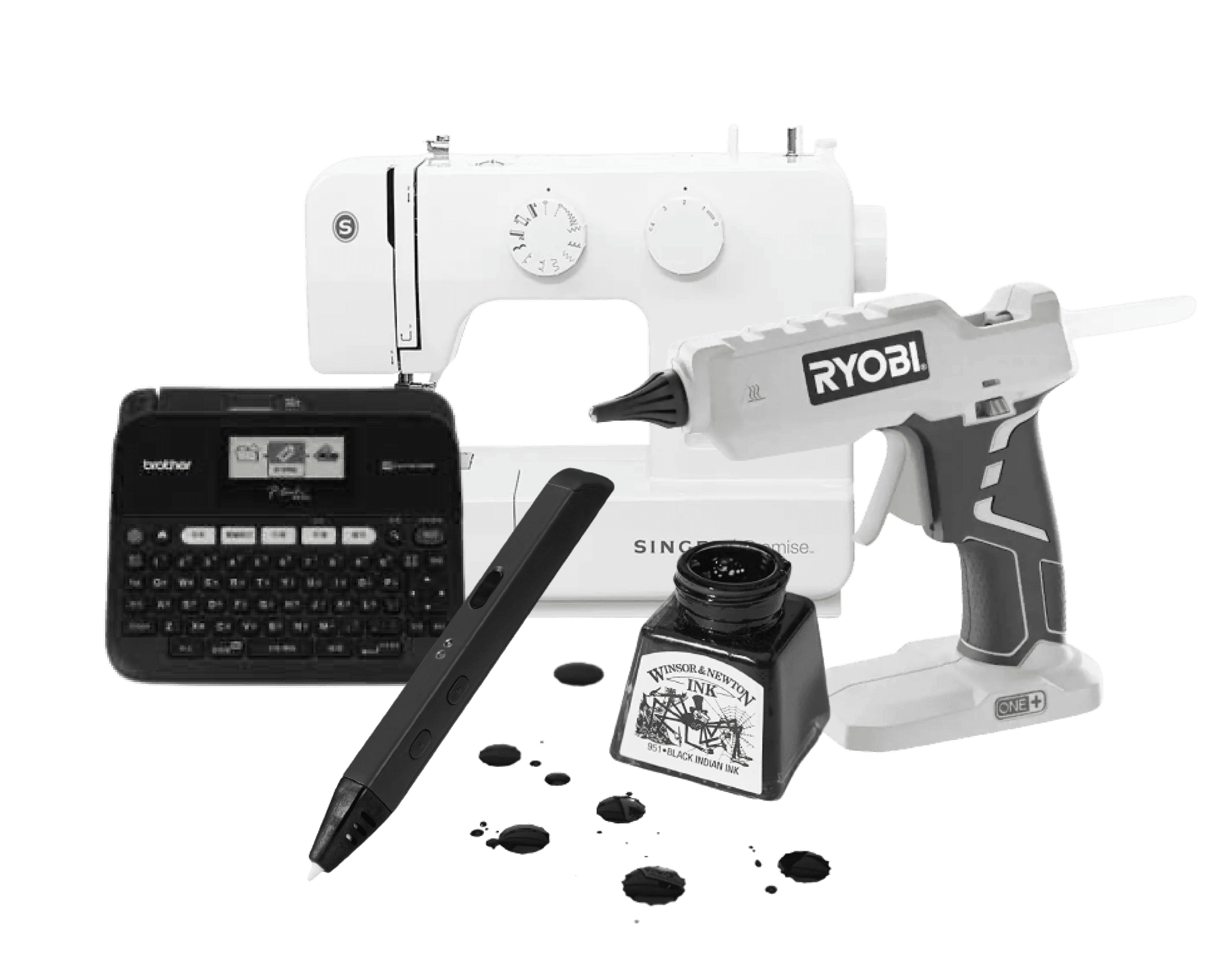

Touchable Ink & Glue Guns & 3D Printing Pens

Allowing paper printers to leave highly visible marks on the paper. However, these devices are less feasible to prototype due to the high temperature needed for melting and printing with accuracy.

Fully Automated Sewing Machines

Efficient and have a similar embossing mechanism. Nevertheless, they are pricey and heavy, making them incompatible with the design goal.

Portable Thermal Printers & Label Printers

Although the labels may fade over time, the structure of the printer provides high mobility and usability. If the labels can be created with indentation, then the features of thermal and label printers will be ideal for the proposed project.

Manufacturing Techniques

Hardware

The physical components of the project contain a printer head, which is attached to a handle that will print the Braille script column by column. A conveyor belt will be constructed for the delivery of the tape. The speed of the conveyor belt will be set by default to match each movement of the printer head.

Software

The software will be programmed for the system to translate the input text into Braille equivalent and electronic signals, which will be sent to the hardware.

02 CONCEPT

Primary Features

Print Braille Label

The machine will be able to print out Braille onto a surface. The Braille printer can be used to print on thick tape. The user can take out the tape and stick it anywhere they want so that a person with a disability can read the Braille by touching and feeling the indent on the stickers.

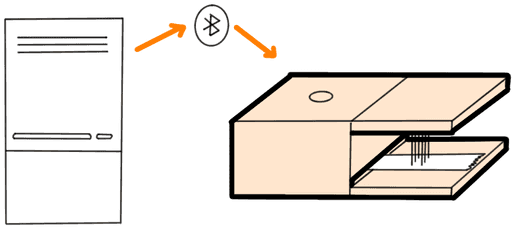

Translate

The machine will read the user input and translate it into Braille. Users can type English letters or words into the machine through a text editor, which can be on the machine itself or linked to an electronic device. Then the machine will translate that input text into Braille.

Change Surface

The tape that will be used in the machine is changeable. The machine can print on different physical interface types by changing the tapes.

Custom Size

The machine will have a tape cutter which helps the user easily cut any tape.

Goal

Simple & Convinent

Maintain the simplicity of text input and translation of conventional Braille printing machines and the expediency of sticky label printers and embossing printer heads.

Labels

Produce Braille labels with stickers or Braille scripts with parchment papers given the user’s input from the software.

Fully Automited

Have the printer system fully automated, integrating an x-y bearing structure driven by stepper motors with an embossing head that moves by the serial communication of the position vectors of each Braille dot.

Aesthetic & Portable

The interface and physical structure of the Braille printer should be designed to meet ideal aesthetic requirements and a moderate level of portability.

03 DESIGN

Printer Head

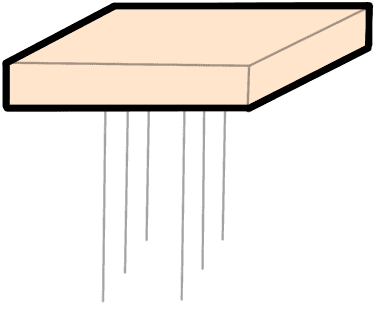

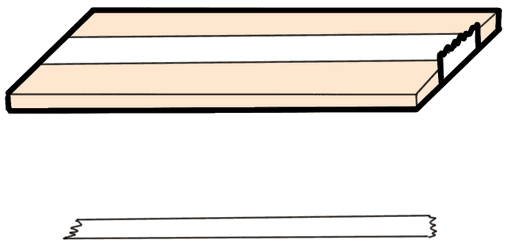

Six-Stylus Printer Head

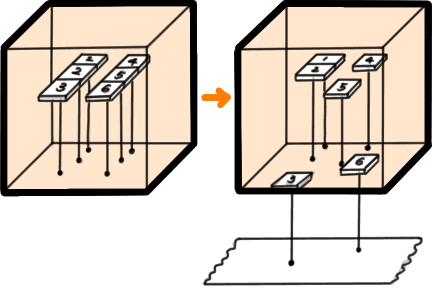

A hammer consisting of six needles in the shape of a 3x2 rectangle should be built around the bottom of the head, with each stylus labeled from 1 to 6 that communicates with the microcontroller.

The horizontal axis structure designed in the framework module will help move the entire head 1 unit to the right. Moreover, additional z-axis needs to be built within the printer head structure. Such a structure allows the printer to move back and forth and facilitates the text wrapping around with a fixed-line space.

Printer Head Moving Structure

Printer Head Printing Process

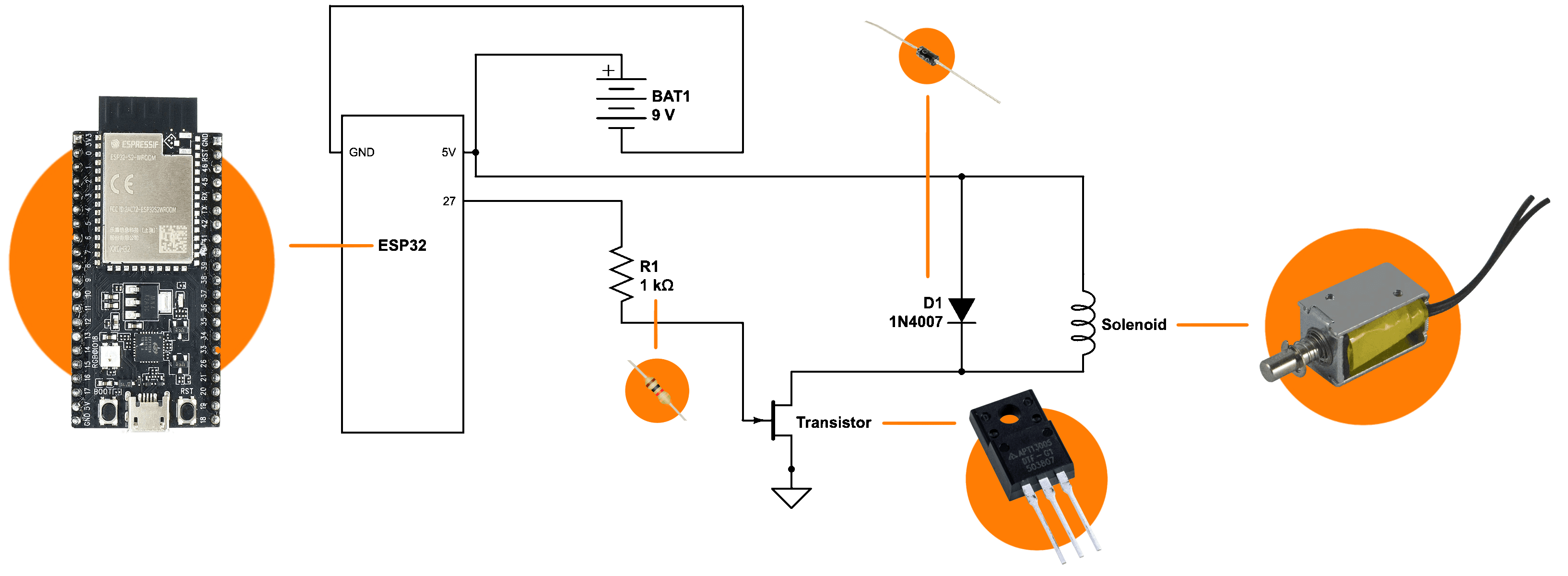

One-Stylus Printer Head with 5V Solenoid

Taking all the testing cases and experiments into evaluation, a one-stylus printer head will be more feasible to implement given that the size of the entire printer head is designed to be relatively small and light-weighted. A 5-volt mini push-pull solenoid valve drives the first implementation of the one-stylus printer head. In this case, the stylus can move by actuating itself and extracting itself back. The primary goal that this first functional implementation achieved is to have the solenoid move upwards and downwards to mark each dot. After a line is finished, the printer head (along with the needle) should move posteriorly on a larger scale to create a new line and finally move anteriorly back to the default position. Therefore, it is designed to be placed on a platform connected to the x-y plotter.

The initial prototype of the printer head can be switched on and off based on the input from the microcontroller. However, its performance still needs improvement. It can only be managed to leave a minimum trace on the paper that needs to be more salient for people to read and touch.

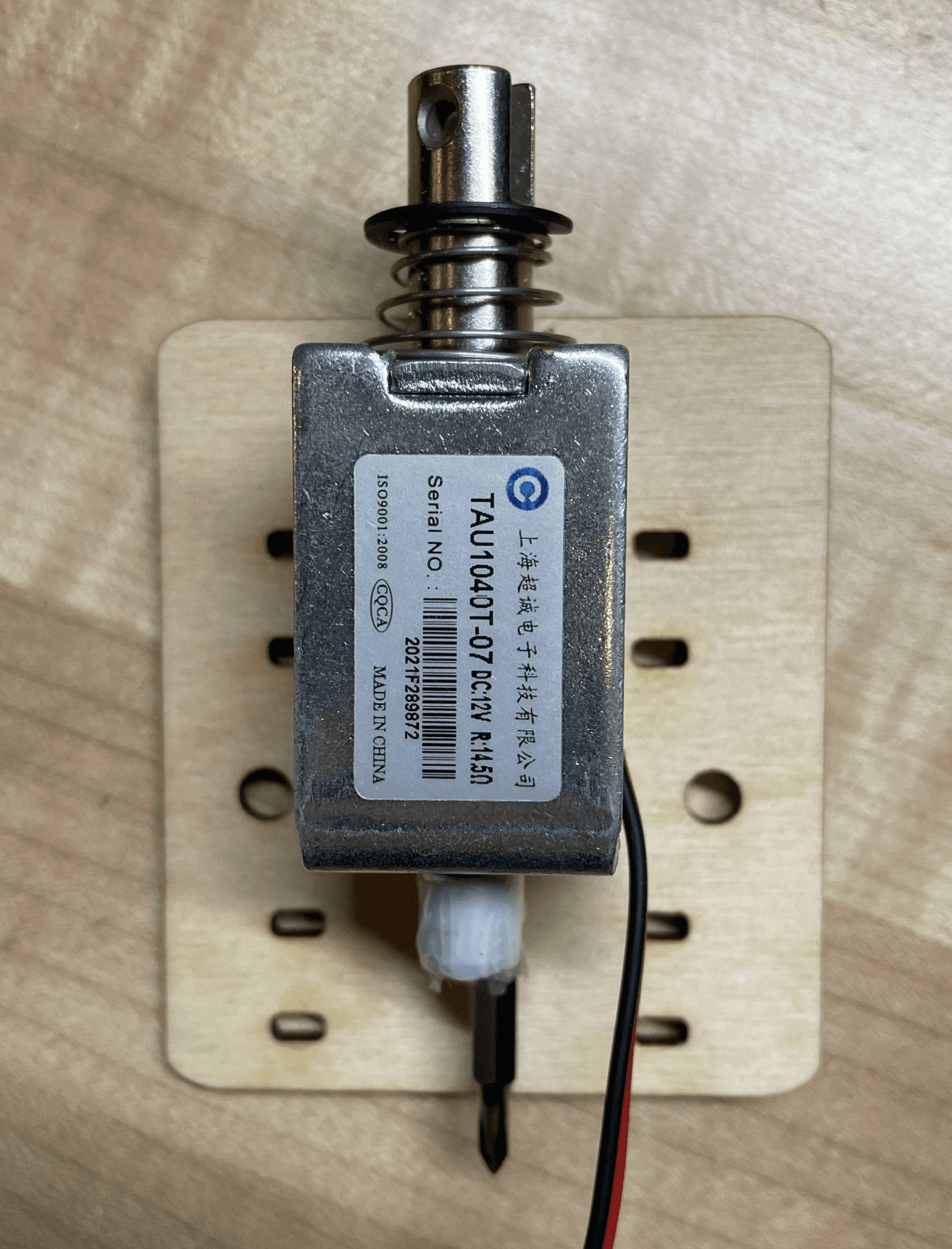

One-Stylus Printer Head with 12V Solenoid

Alternative Paper

The force that the mini solenoid generated will break through the paper instead of leaving an indentation mark on it. Sticker paper is already the most ideal and practical material for Braille printing.

Alternative Solenoid

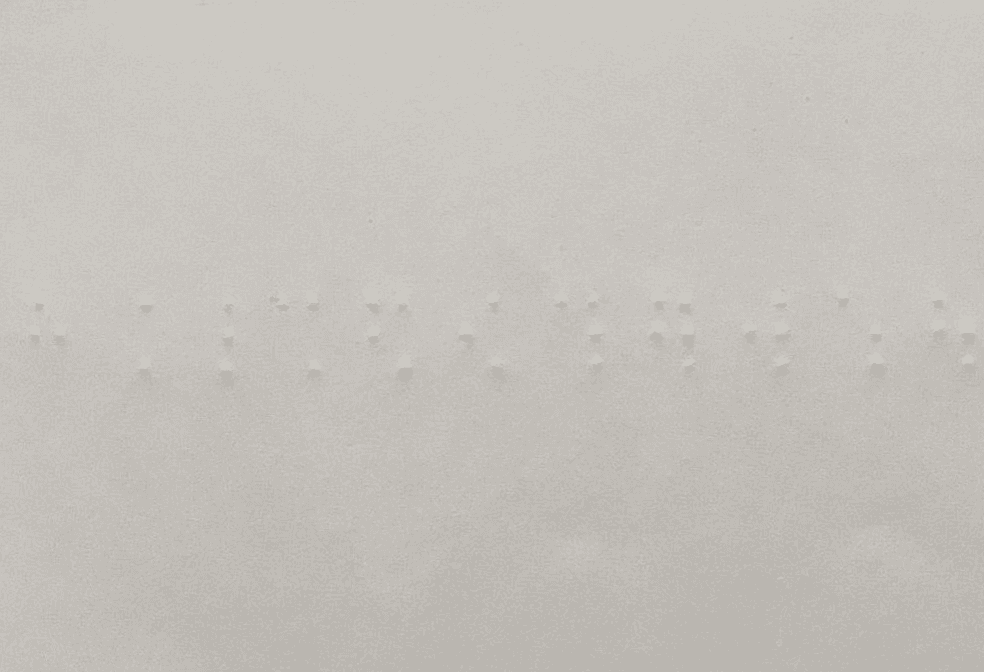

The performance of the 12v solenoid exactly matches the expectation of the printer head, and it generates much greater force and is more capable of leaving proper marks on the sticker paper.

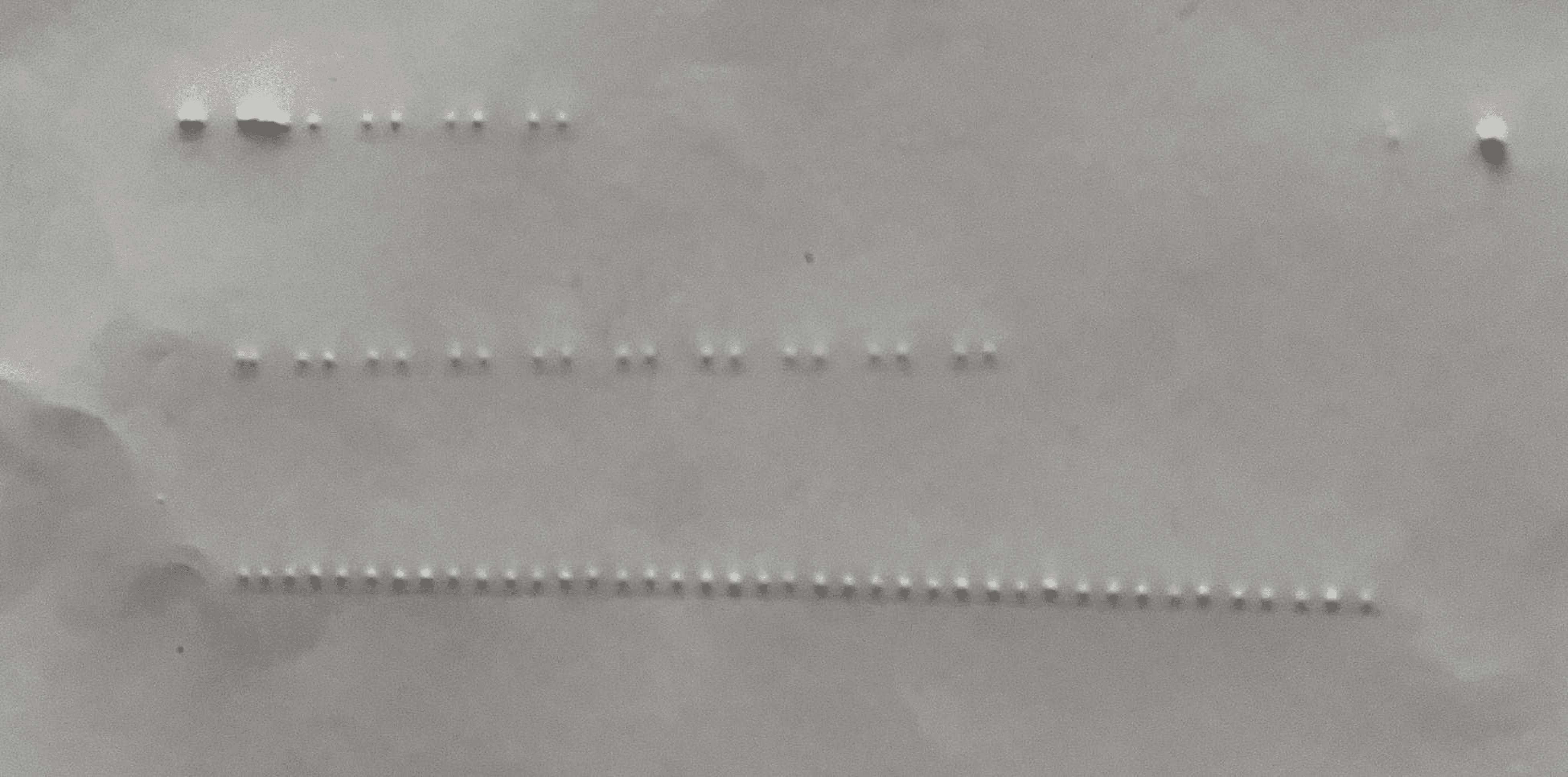

Printing Results of 12v Solenoid

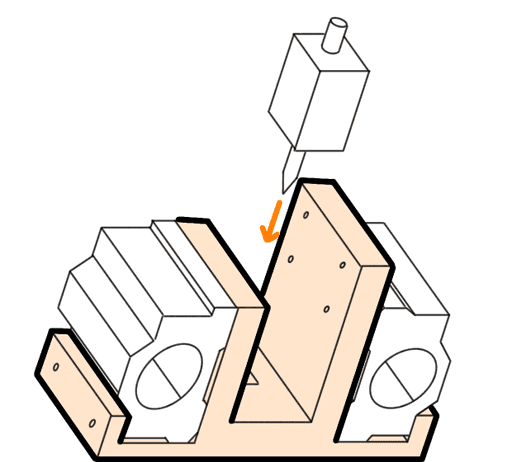

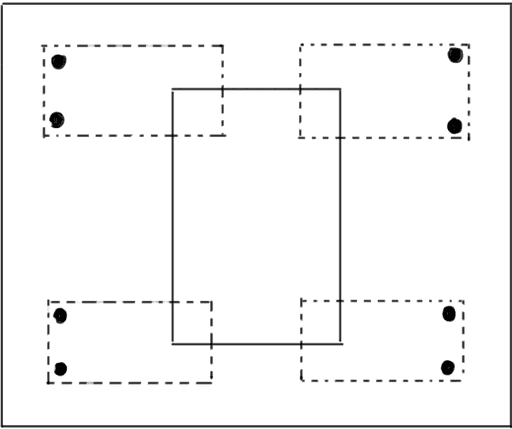

Because the dimensions of the 12v solenoid do not match the design of the mini solenoid, and it is heavier than the first prototype, a new connector needs to be designed.

In this new version of the supporting structure, it has four holes that match the screw position of the solenoid, two holes for the belt to be attached to the board, and another four holes that allow the zip ties to pass through and be able to tie onto the connectors and the rods.

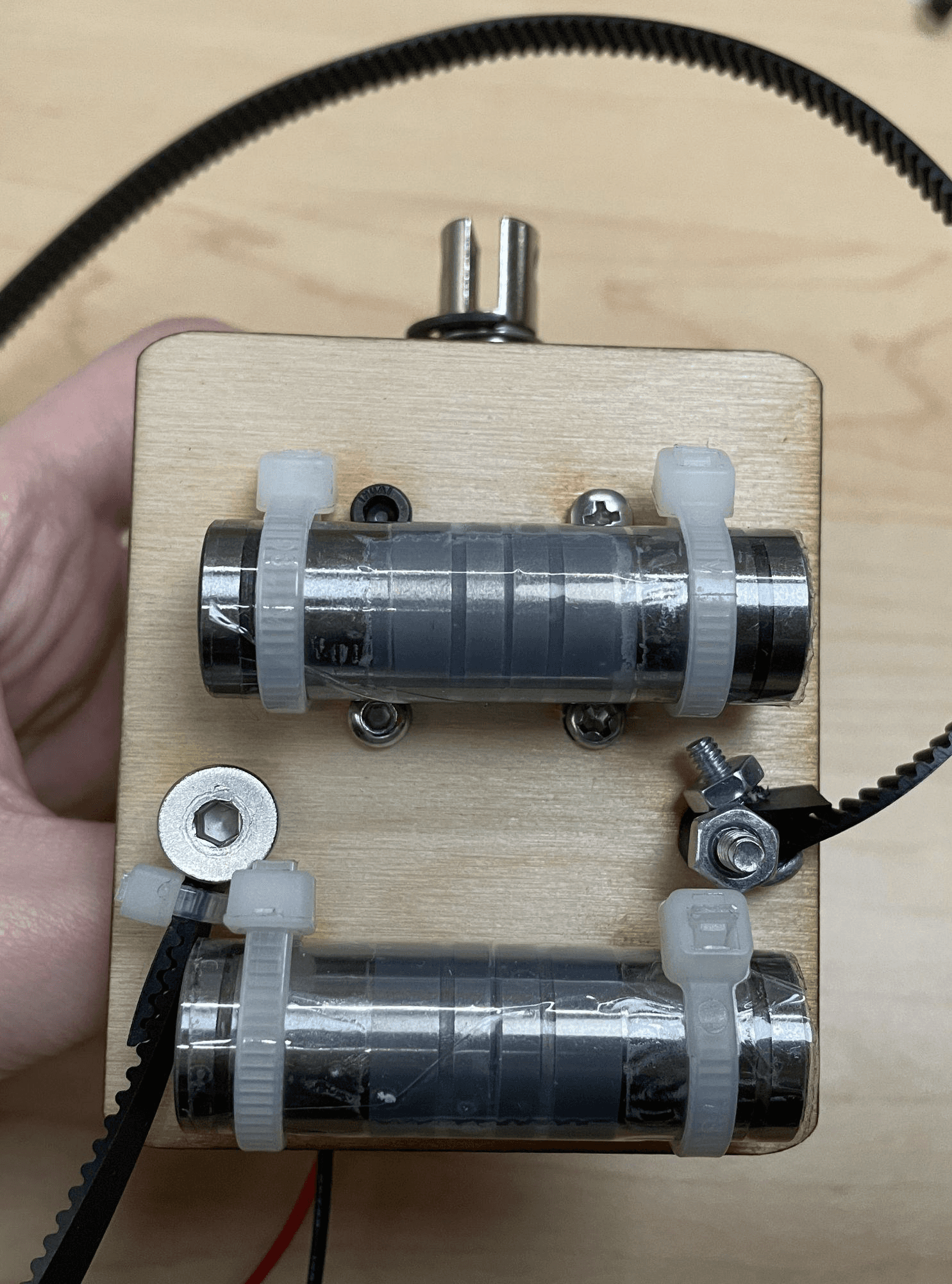

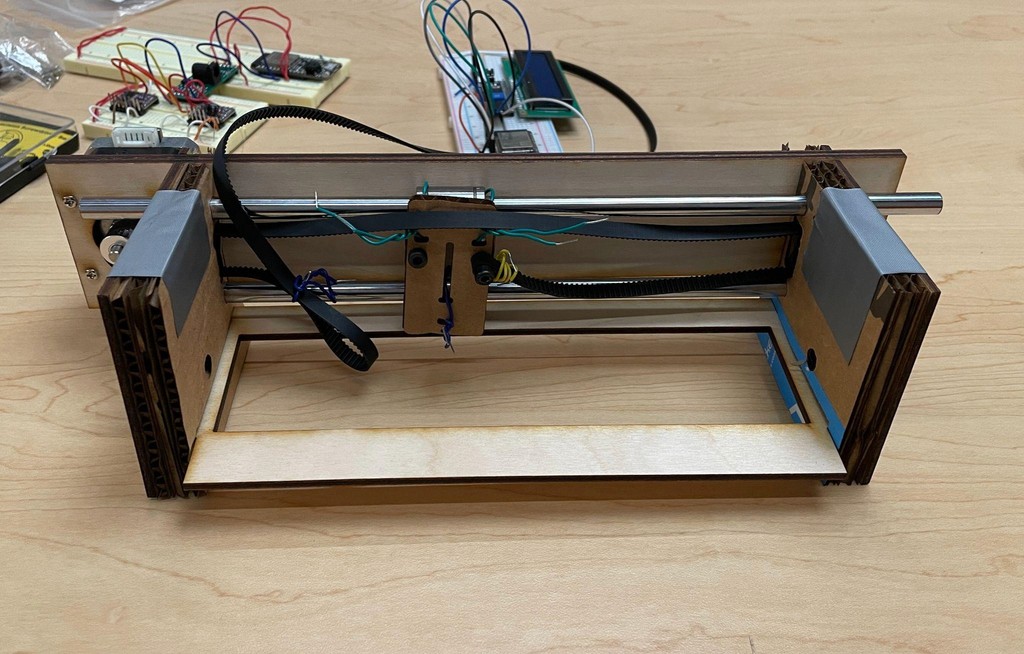

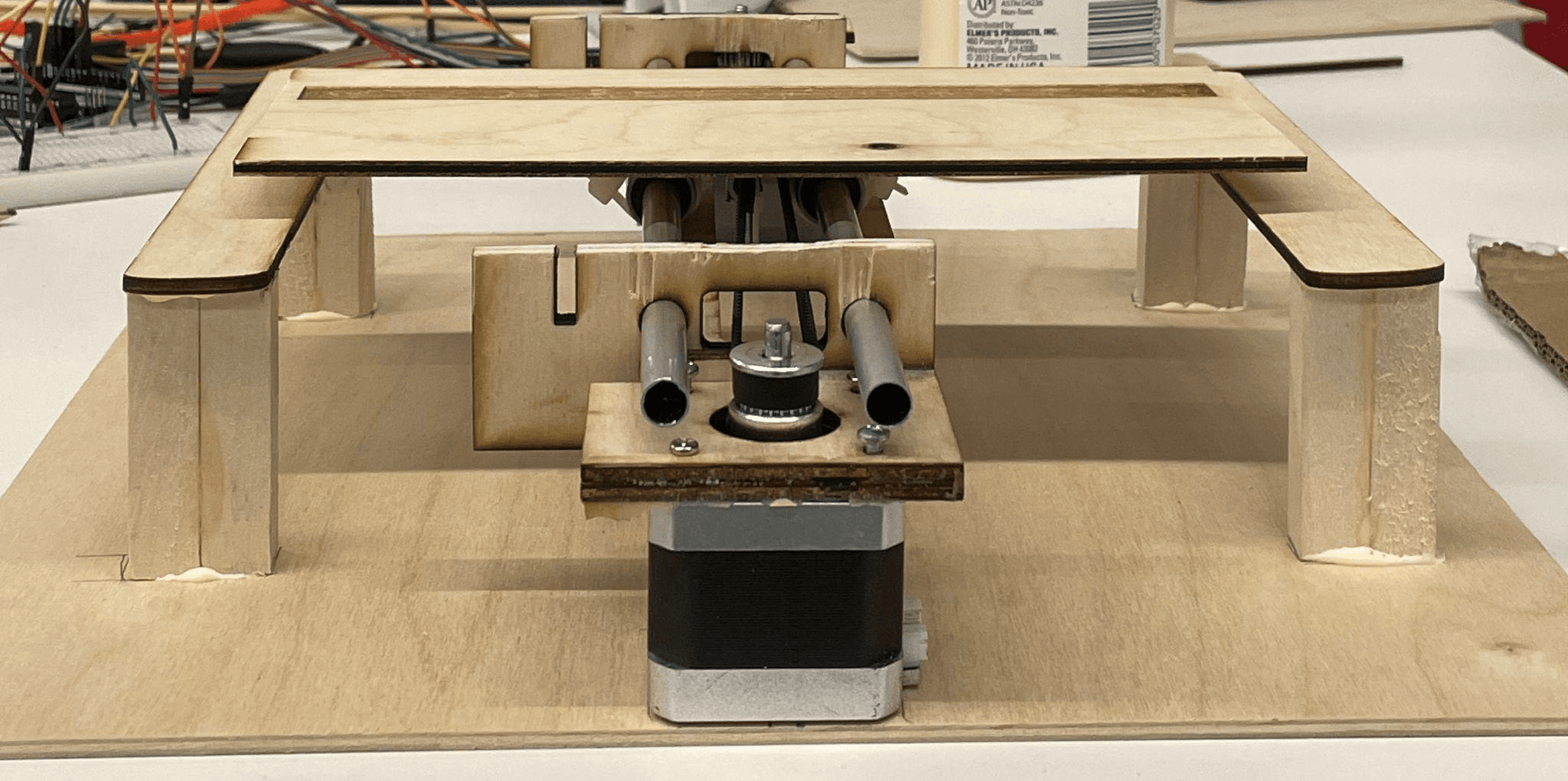

Board Supporter

The second design is laser cut with ⅛ plywood and can be secured tightly to the solenoid and the rods. It is also thin enough to fit into the overall bearing structure without hindering the movement of the belt. The solenoid is screwed onto the board, four rod connectors are connected to the board with zip ties, and two additional screws are attached to the board to connect the belt to the printer head. A screwdriver head is attached to the bottom of the solenoid with glue to leave more salient and deep indentation onto the paper. The final performance of the printer head satisfied the design goal in both the strength of the indentation and the intended smooth movement in the x-axis. It will now be able to move along the x-axis with a stepper motor and leave a relatively strong mark on the paper.

Final Implementation of the Printer Head

Bearing Structure and Framework

The bearing structures of the framework are responsible for supporting the movement of the printer head in both horizontal and vertical directions on a 2-D plane.

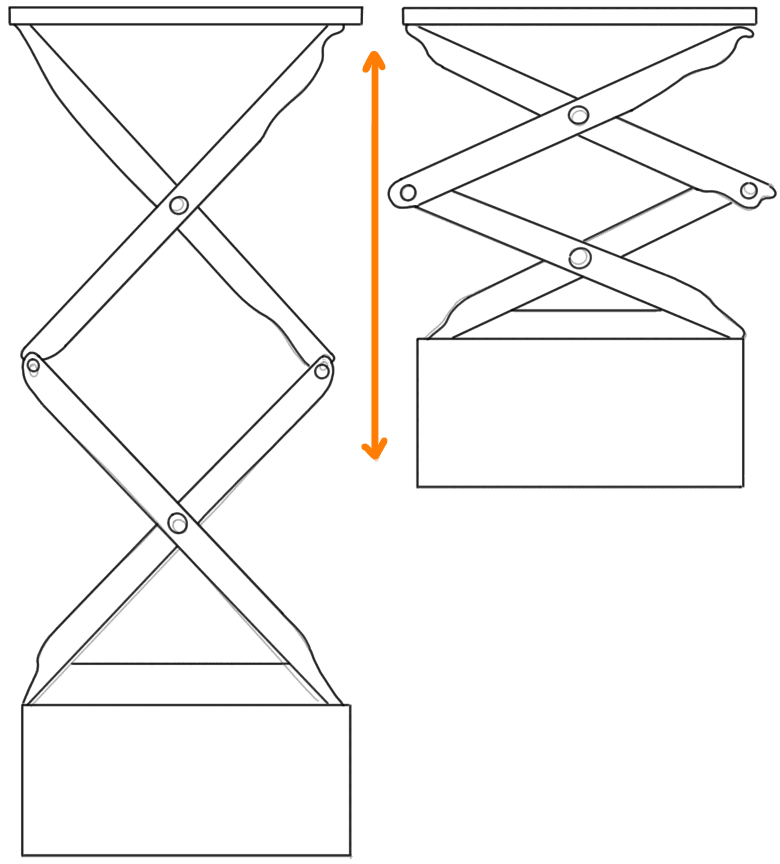

Scissor Lifting Structure

It is commonly seen on elevators and forklifts. It has the shape of the letter “X” and a scissor cross and is usually built at the bottom of a machine to support the platform on top of it. For this project, the scissor lifting will be turned upside down and hung upon the ceiling of the machine so that the printer head can be actuated downwards.

X-Y Axis Lifting Structure

This is derived from the conventional printer and embossing machine with an x-axis and a y-axis with bearing parts connecting to the printer head. With this structure, the printer head can also move horizontally and vertically at a moderate speed.

Once the printer head is attached to it, the total weight of the printer head, sensor tools, and the servo motor itself will be centered on a single point, making circuit connections inconvenient. The structure can be too complex and out of balance if the area of the platform is increased for more stability.

It connects the framework and the printer head with multiple linear bearing rods and platforms. This design ensures that the printer can be moved in the four directions stably and smoothly.

First Version

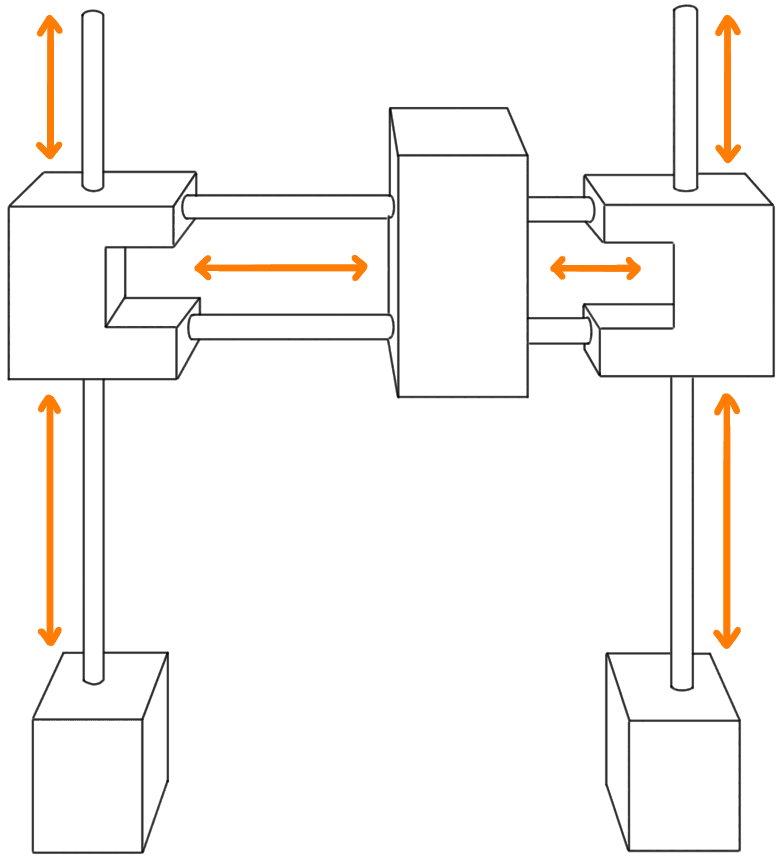

After evaluating the performance of the two prototypes, a 2-D (flattened) version of the conventional x-axis and y-axis model is selected in the final design. This design will render the most flexibility and space for the motors and the printer head. It has four fixed supporting nodes for the framework and stepper motors and four rods to maintain the balance and drive the centered solenoid bearing platform with a pulley belt.

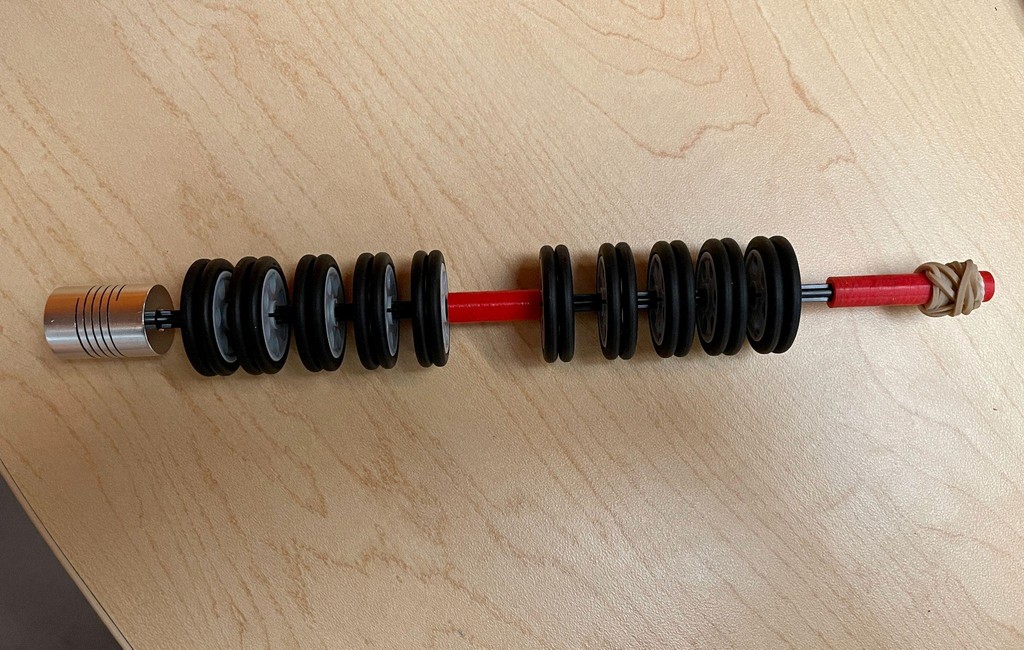

The first version of the final x-y plotter prototype design employs a differential x-y plotter model. A total of 13 parts and joints are printed out with a 3-D printer. The central platform comprises two separate body pieces connected by screws. The bodies have patterns that allow the rods and belts to traverse across three supporting structures and the stepper motor. Two wings and motor caps are attached to the rods and the motors so the motors can drive the entire system with one belt.

The main disadvantage of this differential x-y plotter is that it is complex to build and difficult to control the motors to carry out precise movement given the size of Braille cells. Another concern is the potential constraint of a giant and unbalanced motor unit and central platform that it imposed on the overall designed structure. This plotter's framework also deviates from the design goal of having a portable and convenient Braille printer.

Second Version

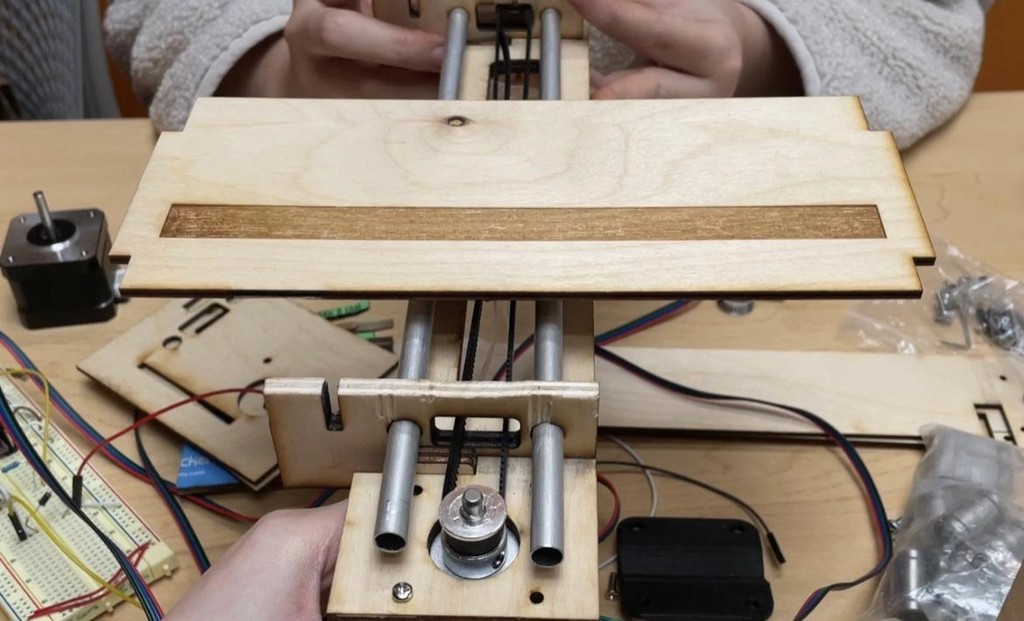

Considering the drawbacks of the last prototype, a new design of the bearing structure is designed to implement the primary design goal and a prototype with improved efficiency and portability. The customized design of the x-y plotter preserves the x-axis of the differential x-y plotter to drive the pulley belt and the motor.

As shown in the upward sketches, the central platform, which holds the solenoid printer head and two linear motion bearing joints, are suspended in midair by two liner rods. One of the ends is connected to a fixed structure attached to the printer machine's wall. Another end of the rods is connected to the stepper motor cap. The cubic concave areas on the sideways supporting structure are used to store the pulley wheels and belt to drive the platform from the front to the back. The y-axis is divided into two linear rods, with one of the rods fixed to the wall to hang up the x-axis and the motor attached to it and another rod connected to the stepper motor to drive the entire x-component to move from left to write when printing out Braille characters.

When the program activates the motor, it drives the central platform, which is steadily connected to the pulley belt. To fully implement the design goal, the final prototype must ensure that the supporting structures, either made of plywood board or metal block, can lift all the machine units while the motors are running. In addition, the current design for the customized parts focuses primarily on the connectivity and motion functionality of the joints. Thus the designs are improved and printed out again with more precise measurements of each part to achieve the targeted stability and integrity.

Unfortunately, this customized design of the bearing structure needs to be fixed for the redesigned printer head module.

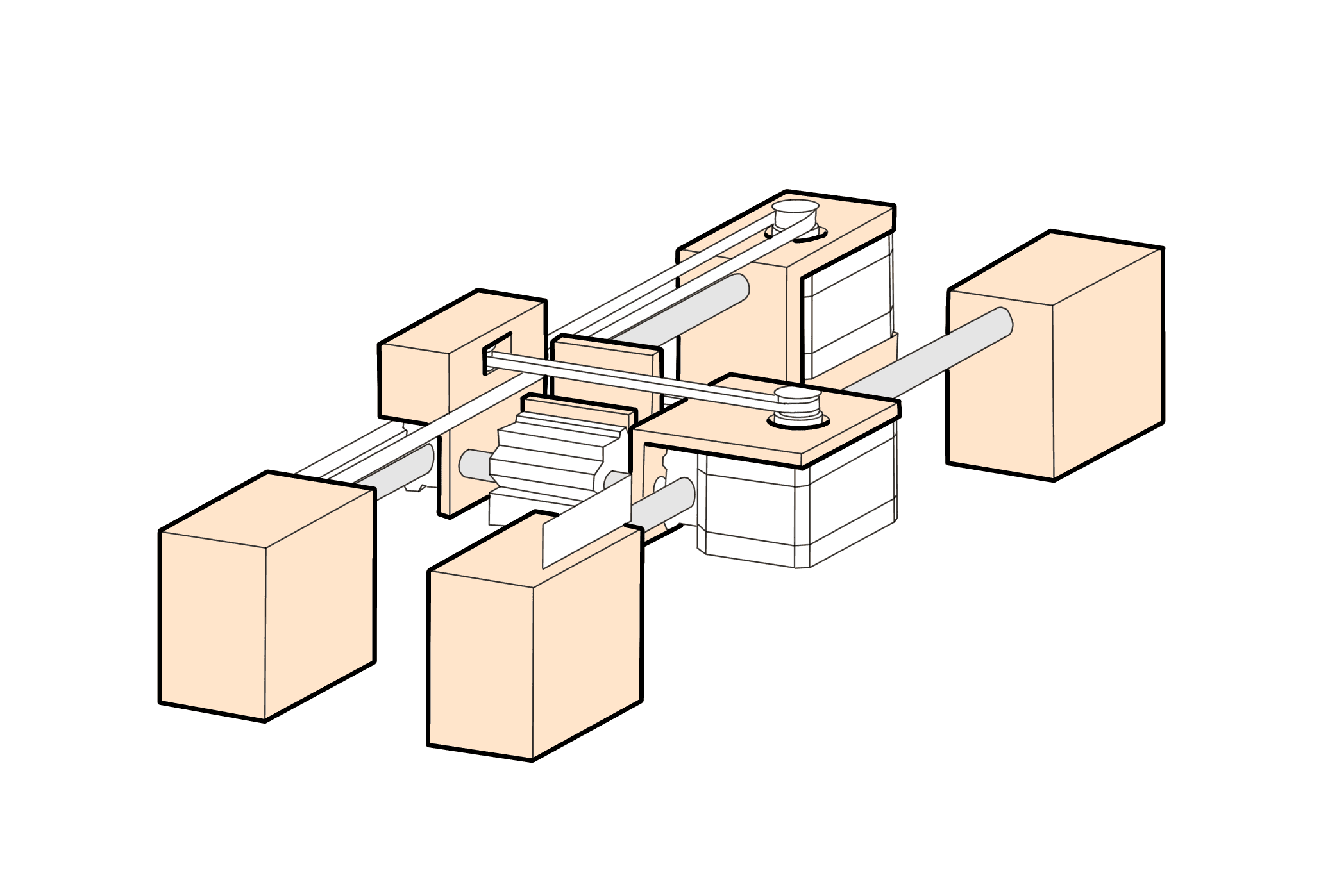

Final Version

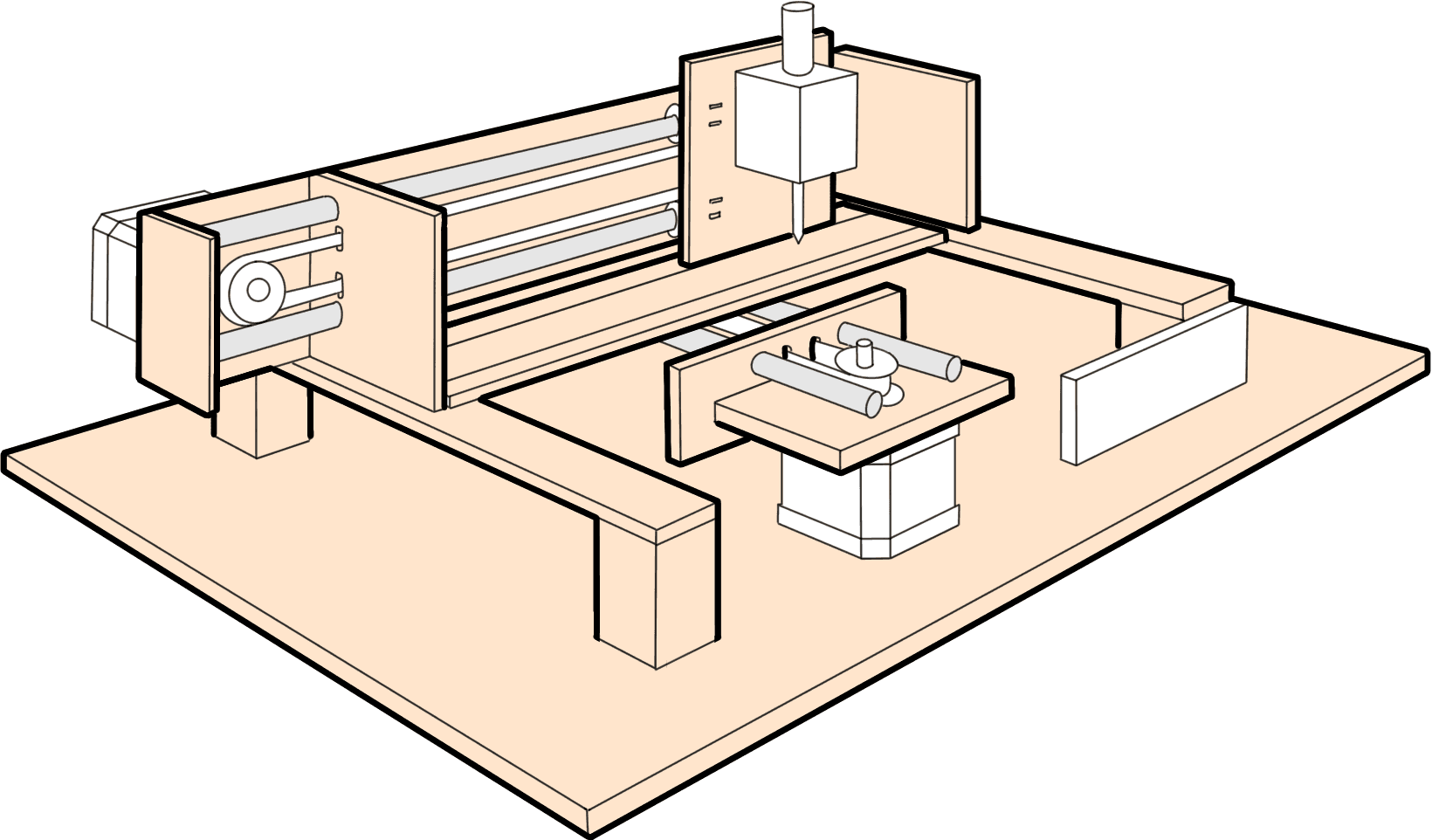

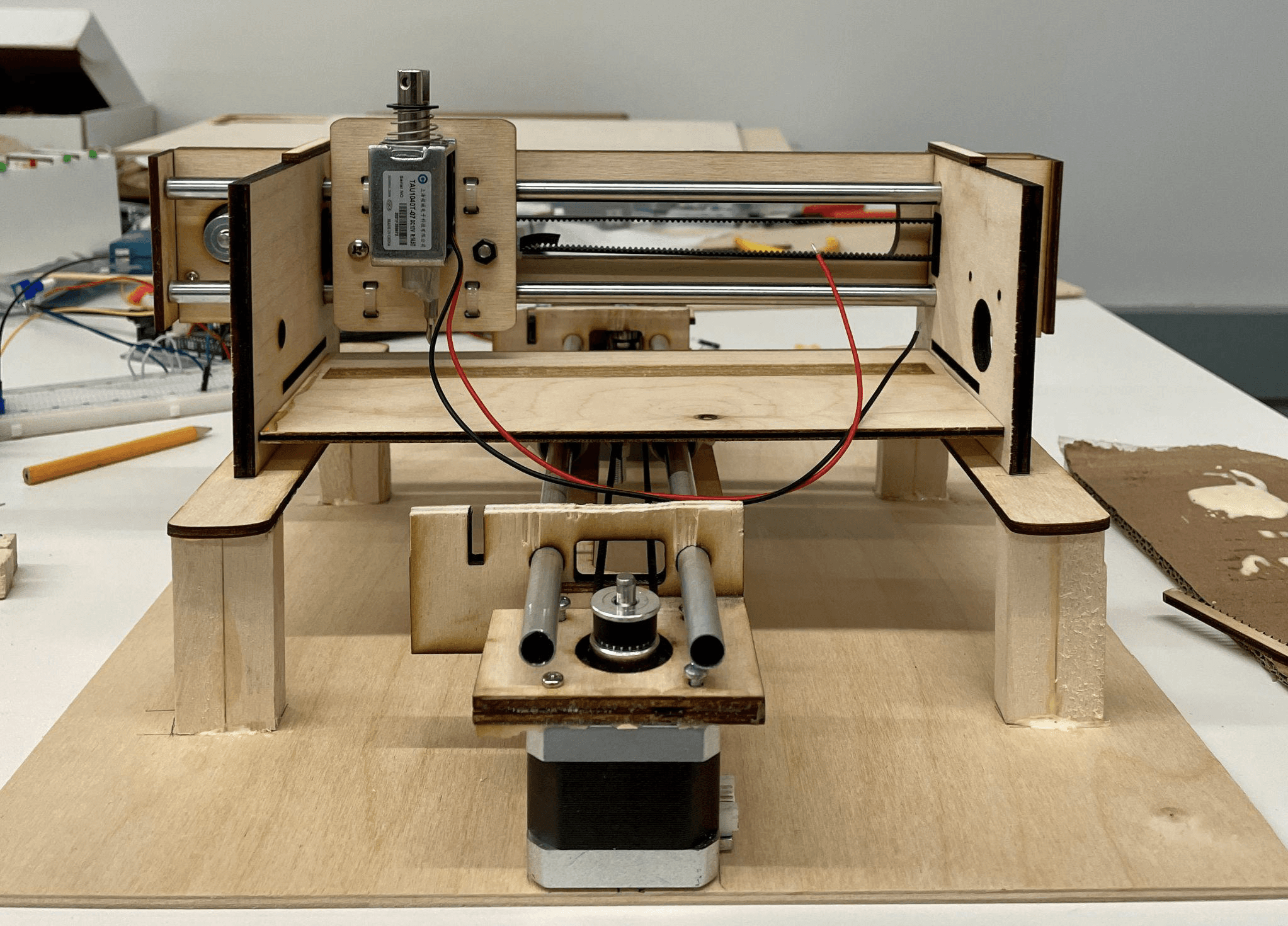

In order to simplify the design procedure and achieve the most efficient design, we decided to break down the bearing structure into the x-axis and z-axis since the solenoid already fulfilled the movement in the y-axis itself. The design is modified into three parts.

Modified Design for the Bearing Structure

First, we designed a simple backboard with four screw holes for the attachment of the stepper motor. This stepper motor is connected to the back of the structure and drives the printer head and the belt to move horizontally.

The second modification is done to the wings on both sides. The structure's wings allow the x-axis rods to pass through and another hole for an additional rod that can move the paper in the z-axis so that the printer head can leave an indentation on the front and back of the paper. The wings are also designed to fit the width and thickness of the back and the bottom plywood plate.

The third step is testing three prototypes to find the best way to move the paper.

Wrap the Rod with Rubber Bands

Since the rubber band can not fit onto the rod as perfectly as a piece of plain and adhesive rubber, it fails to provide stability and accuracy that the braille characters require.

Use Lego Axles and Wheels

The resistance between the wheels and the paper is far from ideal and this structure can not be used to move the paper back and forth in the standard Braille space between the cells and lines.

Paper-Moving Structure

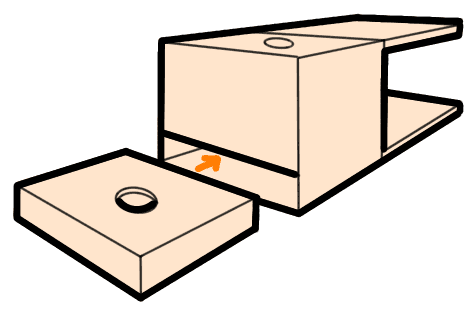

Move the Bottom Plate

Because the movement of the paper is too unpredictable given its weight and thickness, but the movement of a wood plate that can be tightly attached to the moving structure is much easier for us to control and program.

Modified Bearing Structure Design

During the integration of the final design, we noticed another issue with the printer head and the bottom plate. When the solenoid hits the paper on a solid platform, its force will be reduced as the platform underneath the paper can be seen as a buffer. After closely examining the Braille plate for handwriting, we realized that the most salient indentation relies on grooves to help the stylus mark the paper in the greatest strength without breaking through the paper. Thus, we redesigned the moving plate.

Finally, after all parts are ready to be integrated, we use wood glue to build up the final implementation of the design. The bearing structure now has a moving structure that drives the paper and the printing plate on the z-axis and another moving structure that drives the solenoid printer head on the x-axis. The final design's performance satisfies the bearing structure's original design goal. It moves smoothly and stably in both directions, and the distance of each movement has been tested to be as accurate as the standard Braille writing systems.

Final implementation of the Bearing Structure

Translation Software

Receiving text input in English.

Translating each letter into corresponding Braille characters.

Sending output signals to the microcontroller to control the machine's start and the needle's movement.

For each Braille cell, the program will initiate the x-axis and y-axis, then order the solenoid to be set as high and then low to make one embossing happen. Such setup allows us to systematically plot each Braille cell, which will be used later in embossing the 26 alphabets and other punctuations.

1

2

3

4

5

6

Braille Cell

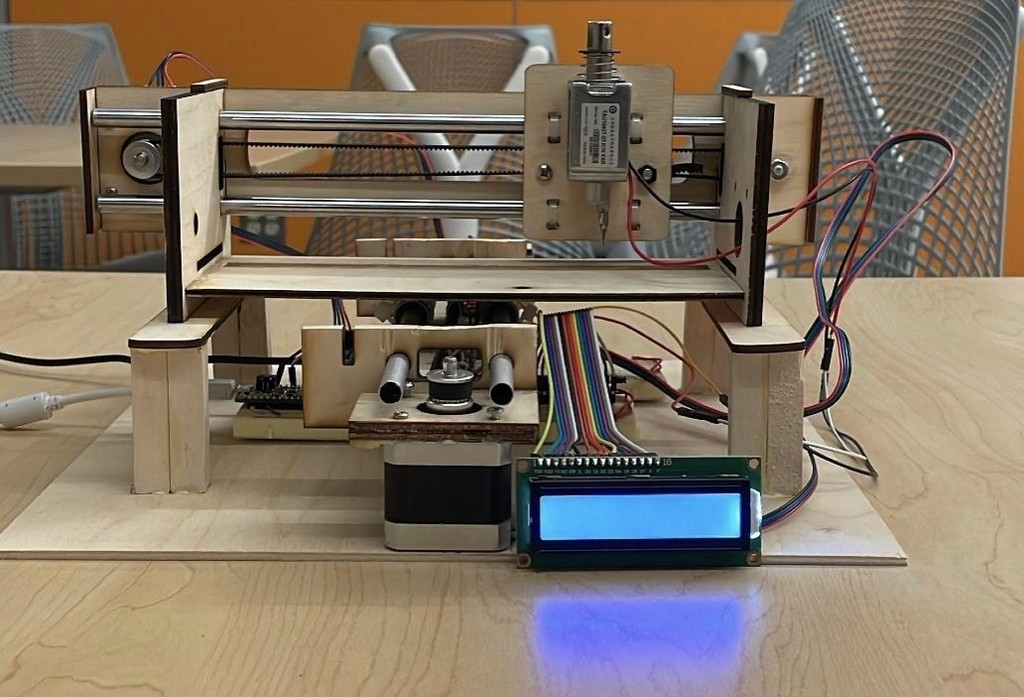

Each alphabet or punctuation will be coded so that it has its full Braille character to be displayed on the computer screen. Other than that, the letter that is printing right now will also be showing on the LCD screen, this will make the Braille embosser more user-friendly. The final braille printer prototype can print out all Braille characters based on The Rules of Unified English Braille Second Edition 2013.

Braille Embosser with the LCD Screen

Braille Characters Printed out by the Final Prototype

REFERENCE

Brother P-touch cube PTP300BT | Wireless Label Maker. (n.d.). Retrieved from https://www.brother-usa.com/products/ptp300bt.

Cheap "Touchable Ink" Brings Everything to Life for Visually Impaired People. Tech in Asia. (n.d.). Retrieved from https://www.techinasia.com/touchable-ink-for-blind-partially-sighted-people.

Gierenz, G., & Karmann, W. (2001). Adhesives and Adhesive Tapes. Wiley-VCH.

Henderson Sewing. (n.d.). Retrieved from https://hendersonsewing.com/page.asp?p_key=B1F3D4F2D10346119EBE96CC0AD409A2.

How Does a Thermal Printer Work? Everything you Need to Know. CDW. (n.d.). Retrieved from https://www.cdw.com/content/cdw/en/articles/hardware/what-is-a-thermal-printer.html.

Imeri, A., Russell, N., Rust, J., Sahin, S., Fidan, I., & Jack, H. (n.d.). Board # 127 : MAKER: 3D Pen Utilization in 3D Printing Practices. 2017 ASEE Annual Conference & Exposition Proceedings. https://doi.org/10.18260/1-2--27723

Noe, R. (2017, August 15). The SEWBOT, a Fully Automated Sewing Machine, Is Cool. It’s Also Bad News for Garment Workers. Core77. Retrieved from https://www.core77.com/posts/68389/The-Sewbot-a-Fully-Automated-Sewing-Machine-is-Cool-Its-Also-Bad-News-for-Garment-Workers.

Velázquez, R., Arroyo, J., Boukallel, M., & Giannoccaro, N. I. (2020). Design and Implementation of a Low-Cost Printer Head For Embossing Braille Dots on Paper. International Journal of Emerging Trends in Engineering Research, 8(9), 6183–6190. https://doi.org/10.30534/ijeter/2020/206892020

Vrailler: Affordable DIY Braille Label Kit to Learn Empathy. Kickstarter. (2019, August 29). Retrieved from https://www.kickstarter.com/projects/vrailler/vrailler-the-portable-and-easy-to-use-Braille-prin.

What is Braille? The American Foundation for the Blind. (n.d.). Retrieved from https://www.afb.org/blindness-and-low-vision/braille/what-braille.